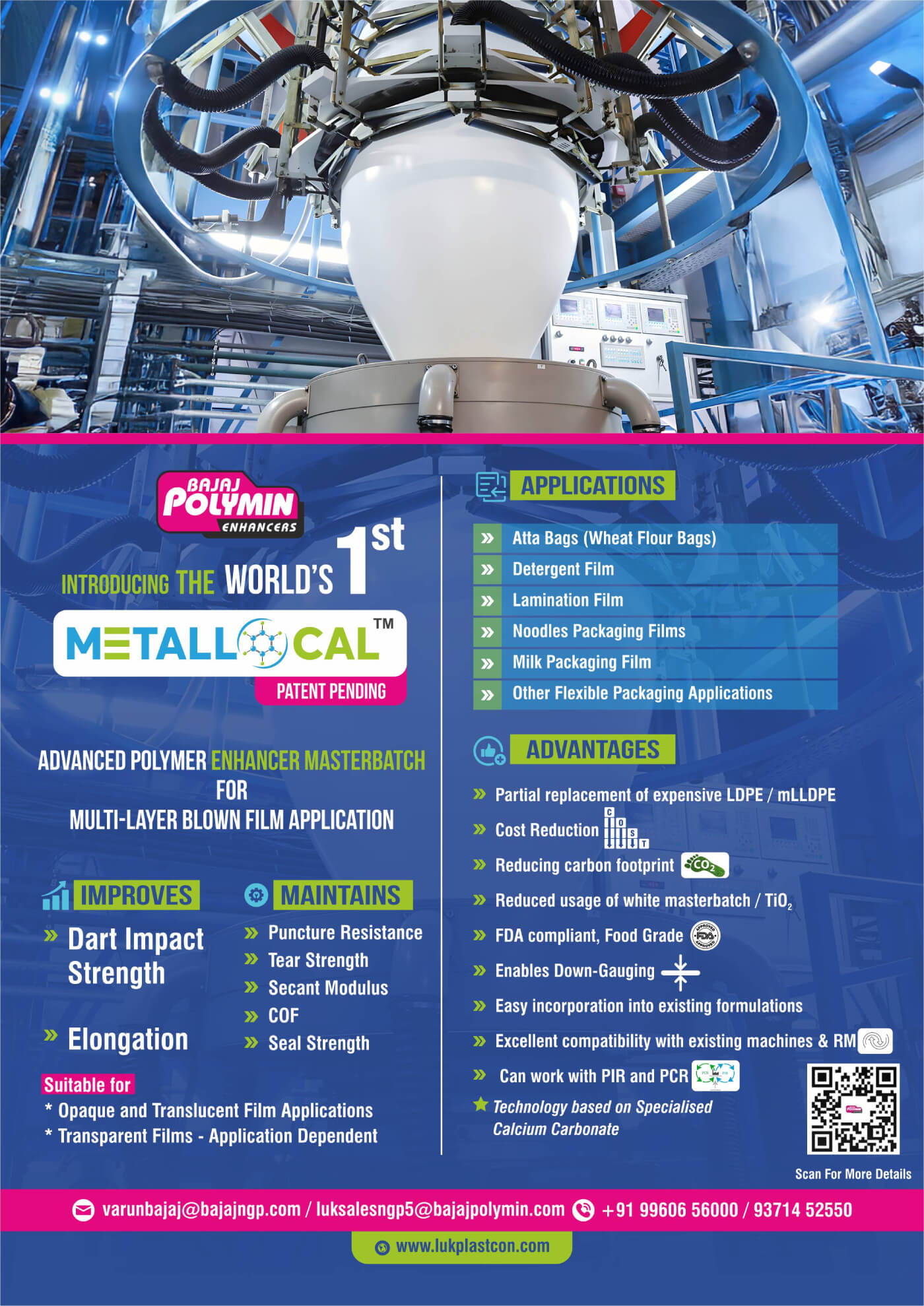

Patent Pending

For Blown films

FEATURES

- Surface-engineered calcium carbonate–based polymer enhancer

- Supplied as a ready-to-use masterbatch

- Designed for multi-layer blown film structures

- Compatible with LDPE, LLDPE, mLLDPE

- Works with virgin, PIR & PCR materials

- Suitable for food-contact applications (formulation dependent), FDA Complaint

- Enables partial resin replacement, Reduces Carbon Foot Print

- Patent-pending technology

ADVANTAGES

- Improves Dart Impact strength and elongation

- Maintains key mechanical properties:

- Tear strength

- Puncture resistance

- Secant modulus

- COF

- Seal strength

- Reduces dependence on high-cost polymers like LDPE/ mLLDPE

- Lowers usage of white masterbatch / TiO₂

- Easy drop-in solution— no machine modification required

- Stable processing with good dispersion

- Supports down-gauging initiatives

BENEFITS - WHAT THE CUSTOMER ACTUALLY GAINS

- Lower packaging cost per kg / per pouch

- Ability to down-gauge film thickness without major performance loss

- Improved toughness for handling, transport, and drop resistance

- Stable production with existing formulations and equipment

- More sustainable packaging via Polymer reduction and PCR usage

- Improved profitability without compromising quality

- Faster customer acceptance due to minimal process changes

FAQ

![]() is an advanced polymer enhancer masterbatch based on surface-

is an advanced polymer enhancer masterbatch based on surface-

engineered calcium carbonate, designed to improve mechanical performance and enable

cost optimisation in blown film applications.

No. Unlike conventional CaCO₃ fillers, METALLOCAL™ is engineered to enhance polymer

performance, not merely add loading. It helps retain or improve mechanical properties

while reducing resin cost.

METALLOCAL™ is compatible with:

- LDPE

- LLDPE

- mLLDPE

- Blends containing PIR and PCR

Typical let-down ranges from 5% to 25%, depending on:

- Film structure

- Target thickness

- Mechanical property requirements

- Resin selection

Yes, but transparency is application-dependent.

- Best suited for opaque and translucent films

- For transparent films, trial evaluation is recommended with respect to allowable haze limits

METALLOCAL™ is designed to maintain seal strength and COF within acceptable ranges. Final performance depends on:

- Let-down level

- Film structure

- Additive package

No. METALLOCAL™ enables partial replacement of expensive polymers, not full substitution. The goal is cost optimisation with performance balance.

METALLOCAL™ is FDA approved

METALLOCAL™ is suitable for food-contact applications, subject to:

- Compliance of base polymer

- Final formulation

- Applicable FDA / food-contact regulations

No major changes are required. METALLOCAL™:

- Processes well on existing blown film lines

- Has good dispersion

- Does not require special screw or die modifications

- Enables down-gauging

- Reduces overall polymer consumption

- Supports PCR / PIR usage

- Helps lower the material-related carbon footprint

METALLOCAL™:

- Reduces dependency on TiO₂

- Adds mechanical value, not just opacity

Delivers cost + performance benefits together

- Atta (wheat flour bags)

- Detergent packaging films

- Lamination films

- Noodles packaging films

- Milk packaging films

- General flexible packaging films

- And many more flexible packaging film applications (Contact us to Co-create)

METALLOCAL™ is based on surface-engineered calcium carbonate designed for polyolefin processing.

When used within recommended loading levels, properly pre-dried, and processed under normal PE temperature and shear conditions, it does not cause abnormal screw or barrel erosion. As it does not contain any type of waxes and other harmful additives.

Best Practices to Minimise Wear:

- Follow recommended loading limits

- Always pre-dry METALLOCAL™

- Avoid excessive shear and overheating

- Use standard nitrided or bimetallic screws for long-term operation (recommended for any mineral-filled system)

Under normal operating conditions, wear behaviour is comparable to other mineral-based masterbatches used in blown film extrusion.

When METALLOCAL™ is properly pre-dried and well dispersed, no significant reduction in filter or screen pack life.

Guidelines for Optimum Filter Life:

- Always pre-dry METALLOCAL™ to avoid agglomeration

- Use recommended screen mesh combinations

- Avoid sudden increases in loading level

- Maintain stable melt temperature and pressure

METALLOCAL™ itself does not negatively impact bubble stability when used correctly in the middle layer. However, since LDPE contributes melt strength, its reduction must be balanced by film structure design.

Best Practices for Bubble Stability:

- Keep skin layers rich in LLDPE / mLLDPE to maintain melt strength

- Avoid reducing total LDPE across all layers at once

- Increase METALLOCAL™ loading step-wise

- Monitor BUR and frost line height during trials

With proper layer balance, bubble stability remains comparable to the base film, even at higher METALLOCAL™ loadings.

The middle layer is ideal because:

- It carries bulk, stiffness, and toughness

- It is not seal-critical

- Optical impact is shielded by skin layers

You can replace expensive LDPE / mLLDPE safely

How to use Metallocal in middle layer of blown film?

SOP – Processing & Usage of METALLOCAL™

Middle Layer Application in Multi-Layer Blown Film

1. Purpose

To define the standard operating procedure for effective use of METALLOCAL™ polymer enhancer masterbatch in the middle layer (B-layer) of multi-layer blown film to achieve Balanced Mechanical performance, cost optimisation.

2. Scope

Applicable to 3-layer blown film lines processing:

- LDPE

- LLDPE

- mLLDPE

- PIR / PCR blends

METALLOCAL™ shall be used in the middle layer.

3. Material Preparation (Recommended)

- Pre-dry METALLOCAL™ before processing

- Temperature: 85 °C

- Time: 30–45 minutes

- Use hot air hopper dryer or tray dryer

- Process material immediately after drying to prevent moisture re-absorption

Purpose:

Improves dispersion, stabilises processing, and ensures consistent mechanical and optical performance.

4. Initial Trial Setup

- Start with 10% METALLOCAL™ in the middle layer, replacing LDPE

- Keep the following unchanged versus base film:

- Film structure

- Layer thickness distribution

- Screw RPM

- Die gap

- Blow-up ratio (BUR)

5. Processing Control

- Monitor middle layer extruder motor current

- If motor current reduces by ~5 A:

- Reduce middle layer barrel temperatures by 2–5 °C

- Adjust zone-wise if required

- Observe:

- Bubble stability

- Melt consistency

- Output stability

6. Property Evaluation (At Each Loading Level)

Compare film with and without METALLOCAL™ for:

Optical & Dimensional

- Opacity

- Film thickness & uniformity

Mechanical

- Dart impact strength

- Tensile strength (MD / TD)

- Elongation at break (MD / TD)

Surface & Functional

- Surface treatment level (dyne/cm)

- Seal strength

- Coefficient of friction (COF)

7. Incremental Loading Procedure

- Increase METALLOCAL™ loading in steps of 5%:

- 10% → 15% → 20% → 25%

- Replacement sequence:

- Replace LDPE first

- Then partially replace mLLDPE, if required

- Repeat Sections 5 & 6 at each loading level

- Do not reduce skin layer thickness during trials

8. Final Loading Selection Criteria

Final METALLOCAL™ percentage shall be selected based on:

- Required mechanical performance

- Acceptable opacity

- Seal strength and COF stability

- Down-gauging feasibility

- Cost per kg and cost per m²

- End-use application requirements

9. Recommended Operating Range

- Typical working range: 10–20%

- Higher loading (20–25%) recommended when:

- Middle layer ≥50% of total thickness

- Skin layers provide toughness & sealing

- Application permits higher opacity

10. Do’s & Don’ts

✅ Do

- Pre-dry METALLOCAL™ before use

- Increase loading step-wise

- Maintain strong skin layers

- Evaluate properties at production conditions

❌ Don’t

- Skip pre-drying

- Use METALLOCAL™ in seal layer

- Jump directly to high loading

- Change multiple process variables simultaneously

11. Operating Principle

“Pre-dry METALLOCAL™, introduce it step-wise in the middle layer, optimise barrel temperature based on motor current, and finalise loading based on performance and cost advantage.”